Cold Rolling

Many different processes are used in the manufacturing of metal parts in cold condition, such as blanking and forming, punching, shearing, cold forging, cold extrusion, powder pressing and cold rolling. Most popular grade for this application is our ASSAB XW-42, being traditional D2-type of material (DIN standard 1.2379, JIS SKD 11). However, ASSAB can offer a plethora of problem solvers depending on identified failure mechanisms.

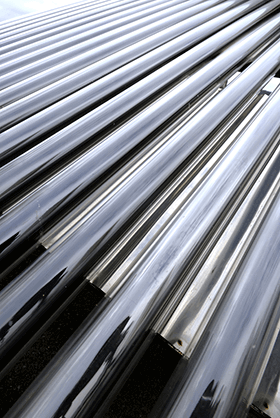

Rolling are classified using the temperature of the metal rolled. Sheets, strips, bars and rods are examples of cold-rolled products. Generally, cold-rolled workpieces are smaller and higher in strength when compared to hot-rolled. Four high or cluster mills would be needed for cold rolling. Cold rolling, however, cannot reduce thickness of workpiece as much as hot rolling in a single pass.

The choice of the best steel for the forming tools must; not only take the process into consideration, but also the type of metal being formed and the number of parts to be produced. In this case, cold rolling is a method used for forming metal by passing metal stock through one or more pairs of rolls to achieve the required reduction in thickness and yet obtaining uniform thicknesses. A tough tool steel is your solution!