Skolvar-Sustainable hot forming solutions

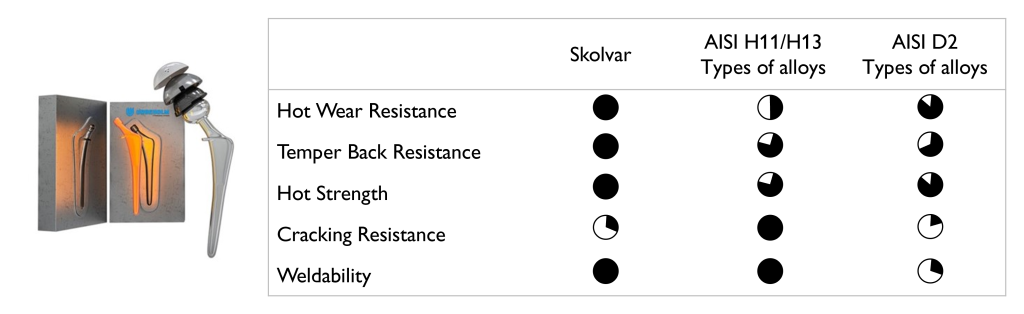

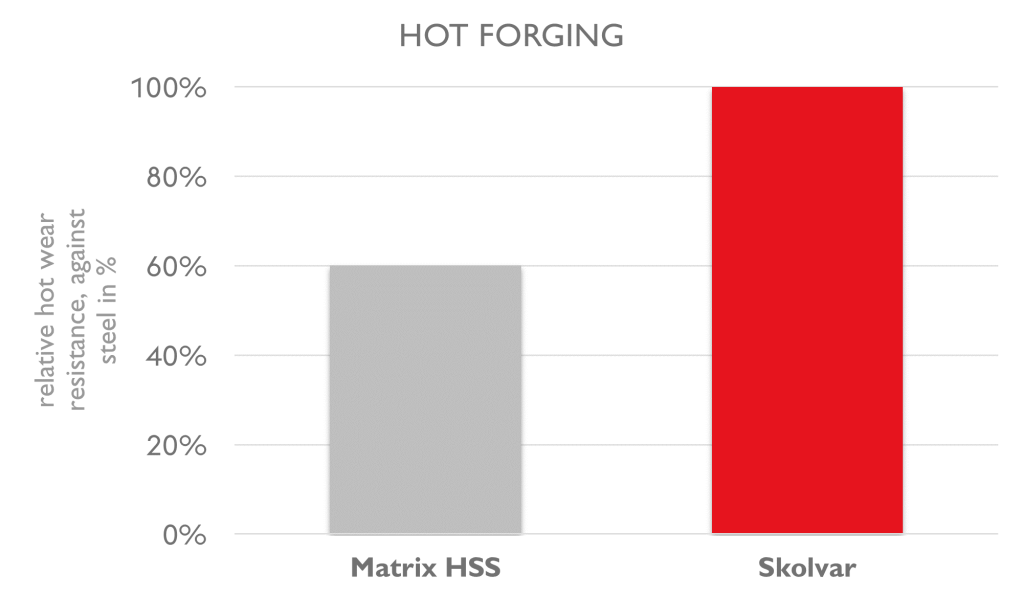

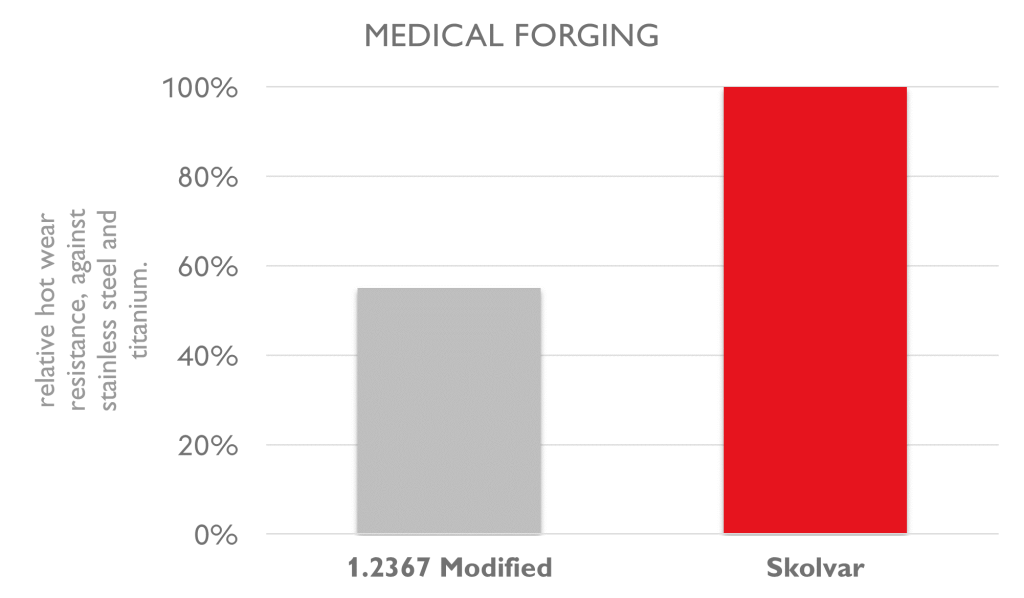

Selecting materials for hot forming dies is challenging due to the need for hot wear resistance. High pressures and temperatures can cause significant wear, compromising dimensional accuracy. Common tool steels like AISI H13 and H11 lack the necessary properties for hot wear resistance, while higher alloyed grades like AISI D2 lack temperature stability for long production cycles. Temper back, caused by prolonged exposure to high temperatures, can reduce hardness, strength, and wear resistance. Alloying elements are essential to prevent temper back. Hot strength is vital to withstand forces without deformation, and Skolvar’s properties resist strength drops during hot forming, enhancing efficiency and reducing maintenance costs for superior tools.

Skolvar is an ideal material for a variety of hot forming applications, including automotive, aerospace, energy, medical, and more.

Find out more >> Introduction of Skolvar